By code, ridge beams are typically necessary in LivingSpace’s Cathedral style sunrooms. The ridge beam is used for structural support on roofs with a pitch of 3:12 or below. For reference, pitches become steeper as they rise in value, meaning a 6:12 pitch is steeper than a 3:12 pitch. Ridge beams can be built for structures with a higher pitch, but they will provide decoration rather than support. LivingSpace relies on ridge boards and SIPS paneling to support these structures.

Ridge Beams

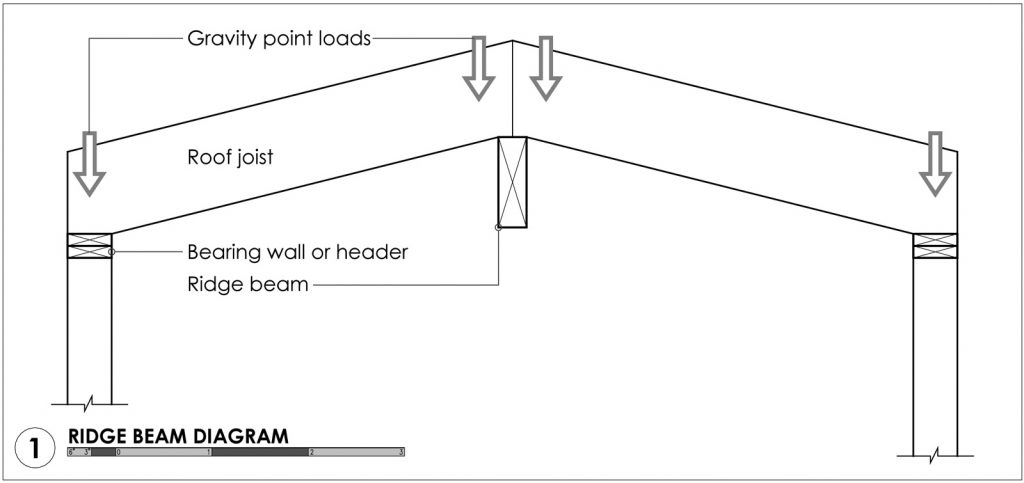

Functionally, the ridge beam supports the roof by holding up the ends of the roof joist at the ridge. This distributes the weight of the sunroom’s roof across the sunroom, with half of it supported at the ridge beam while the other half is supported at the header. The wall post supports the headers by transferring the weight to the sunroom’s foundation.

Ridge beams are created by laminating wood veneer onto reinforced lumber. They are manufactured in different thicknesses and depths. Because of this, LivingSpace can better accommodate all sizes and amounts of snowfall. Likewise, connections between the ridge beam and the roof joists help stabilize the sunroom to prevent wind damage.

Different decorating options are available to make the ridge beam aesthetically fit within the sunroom. One decorating option gives the ridge beam an aluminum skin. It is prepackaged with aluminum attached to each side, while the top and bottom are delivered unfinished. The roof panel is screwed together with the top of the ridge beam, making the unfinished area unseen. An aluminum sleeve is placed on the bottom once the ridge beam is attached to the sunroom.

Another option allows a wood veneer finish to cover the aluminum sleeves. This finish is paintable and stainable to match the mood of the room. With this option, a mounting bracket joins the sunroom’s sleeves together at the middle of the room. Because of this bracket, the ridge beam is able to accommodate a ceiling fan.

LivingSpace’s EcoGreen Panels

LivingSpace manufactures structurally insulated panels (SIPs), pictured above, called EcoGreen panels. They are high performing building panels made from OSB and insulating foam. They are used in the floors, walls, and roofs of LivingSpace’s sunrooms. LivingSpace’s EcoGreen paneling provides excellent insulation that allows people to use their sunroom year-round. However, the Ecogreen panel also provides structural support to the sunroom.

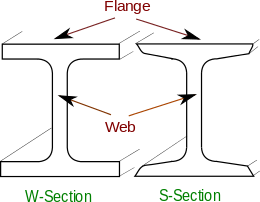

They are self-sufficient and are similar to a steel I-beam in terms of strength and functionality. On an I-beam, there are vertical and horizontal exponents. The OSB acts as the flange by strengthening the EcoGreen panel to maintain position within the structure. The interior foam acts as the web by resisting forces. Through this design, Ecogreen panels eliminate the need for additional framing.